|

Module Legs from Plastic Pipe

|

|

The tops of Free-Mo modules are typically 50" above the floor. Some sort of legs are needed to support the module. These legs are traditionally made from wood. Plastic conduit with screw fittings makes for a light weight alternative. |

.jpg)

Materials needed for four legs:

2 @ 10' lengths of 1 1/2" plastic conduit (I got mine from Lowes)

4 @ male, threaded couplers (Lowes)

4 @ female, threaded couplers (Lowes)

4 @ wood cylinders cut from a 2x4

4 @ 1/4" x 3 1/2" carriage bolts

4 @ 1/4" x 20 Tee nuts

16 @ bolts & nuts to affix the legs to the module

Step 1:

Cut the flared end off of each section of conduit. Set it aside as we will use it later. Cut the pipe into four sections, each 42 3/4" long.

Step 2:

Cut four 4" long pieces of conduit from the remaining

material. Attach it to the female coupler. Cut a 1/2" section

from the flared end of the conduit and put it over the top of the 4" piece.

(note: adjust the length of the 4" piece so that the leg just fits under

your foam.

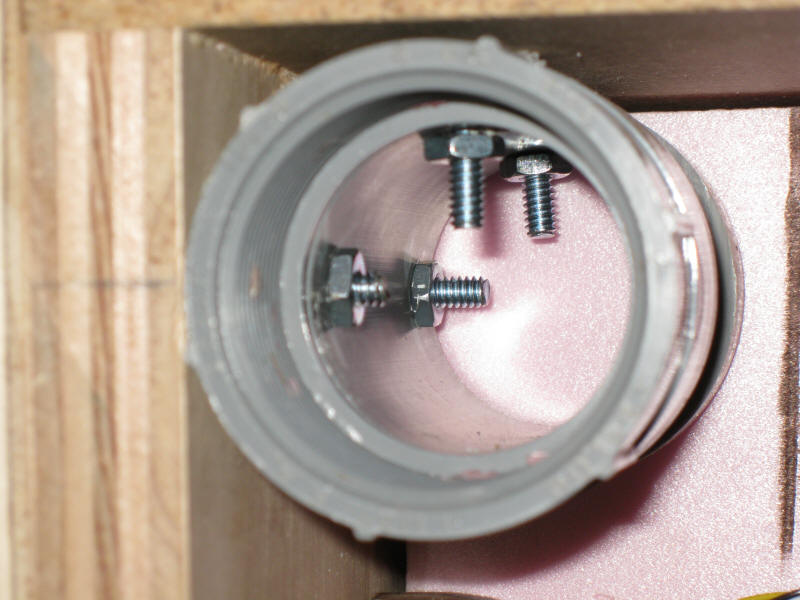

In this photo the section from the flared end is in the upper right and the

female threaded coupler is in the bottom left. The 4" piece connect

them.

Step 3:

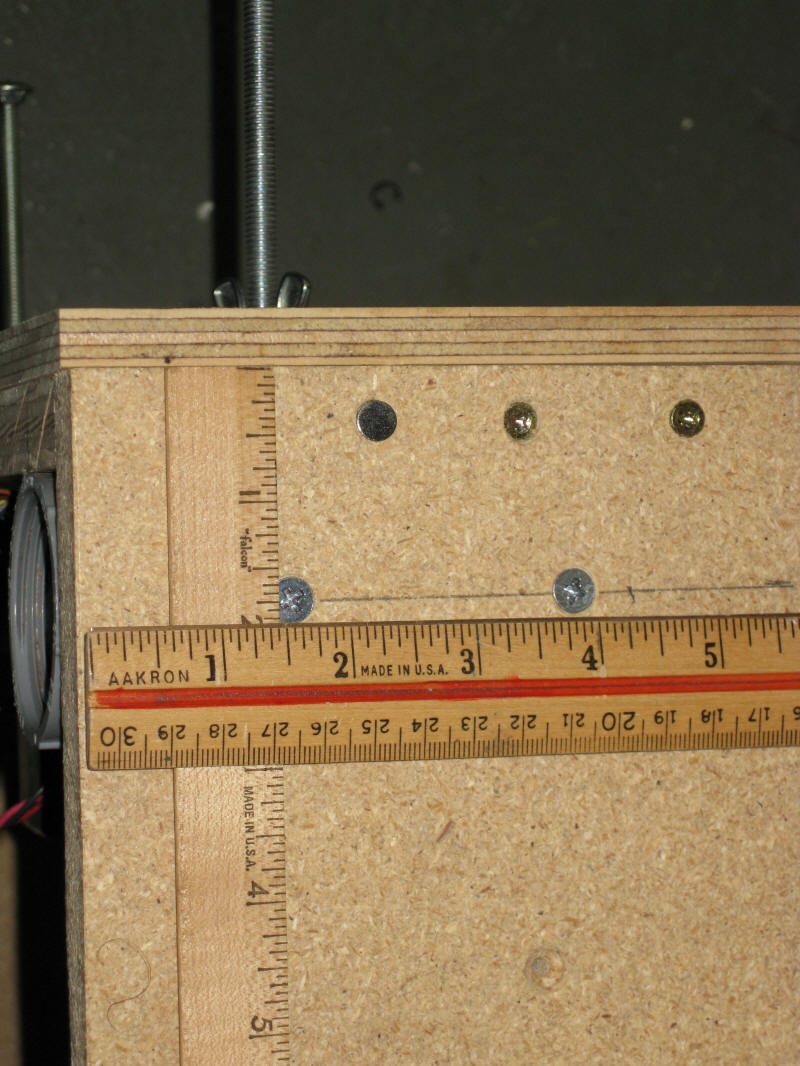

Drill holes through the sides and ends of the module so that they go through the coupler and flared section of the conduit. Note that the holes in the module frame are counter sunk so that the bolt heads are flush with the wood surface.

Put nuts on the bolts inside of the pipe.

Step 4:

Cut four cylinders from a scrap of 2 x 4. Use a 1 3/4" hole saw in a drill press.

Drill out the hole in the cylinder with a 5/16" bit.

Insert each cylinder into the bottom of a pipe section. Drill 3 evenly spaced, counter sunk holes in the bottom of the pipe and screw through the pipe into the cylinder.

Insert a Tee nut into the hole in the cylinder and hammer it in. Thread the carriage bolt into the Tee nut. Note that the Tee nut in this photo has NOT been hammered into the wood cylinder.

The leg "tips" are from the local hardware store:

Step 5:

Glue or force fit the legs into the male threaded section and screw the legs into the module.

DONE!

for information please email

info@shmrrc.org